Construction Access

Systems: SERVICES

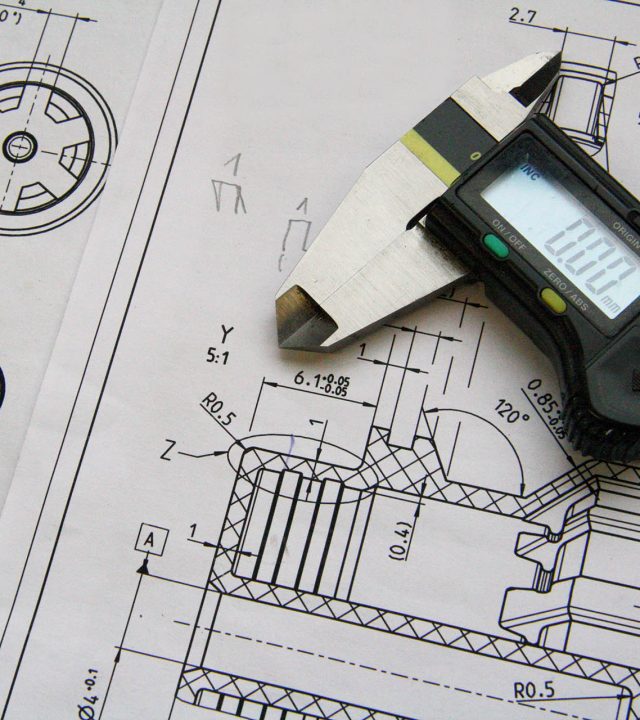

Engineering & Component Testing

CAS Engineering

Construction Access Systems have a wide variety of engineering and component testing experience. For our Common Tower System, project specific design calculations and drawings will be prepared for every use of the Common Tower System specifying the exact bracing layouts, leg configurations, tie quantities and spacing. To back up design calculations CAS has been working with the University of Southampton Research Institute for Industry. A number of tests were performed to determine the buckling load of the leg stanchions of the Common Tower System.

Features

CAS Engineering

At CAS we provide vertical access solutions; provide ideas and technical guidance for tenders through to detailed schemes and for modifications during the construction phase.

We provide project specific temporary works design for the Common Tower System including base, grillage and loading dock platform designs. Solutions designed in 2D and 3D CAD, Revit and structural analysis software. We are also called upon to provide temporary works designs or design checks.

Common Tower System Engineering

The Common Tower is used in conjunction with rack and pinion construction hoists to provide access from the hoist cars into the building under construction, and to provide a means of transmitting the tie forces from multiple hoists to common tie points on the building structure.

The Tower is based on a five metre square arrangement to accommodate conventional twin car single mast hoists or large twin mast single car hoists on any of its faces. The Tower design is modular and capable of adaption to different sizes and shapes to suit various site conditions and to accommodate twin hoists with cars up to two metres wide. The Tower is designed for erection and dismantling either by manual handling of all components or by crane handling of large sub assemblies. The Common Tower can be used on buildings with up to 70 storeys and heights up to 300 metres.

The Tower is designed as a temporary structure using the principles of BS5975:2008 “Code of Practice for Temporary Works Procedures and the Permissible Stress Design of Falsework”. To achieve the low component weights required for manual handling extensive use is to be made of aluminium components and these are designed in accordance with BS 8118:Part 1:1991 “Structural Use of Aluminium”.

Component Testing

To back up design calculations CAS has been working with the University of Southampton Research Institute for Industry. A number of tests were performed to determine the buckling load of the leg stanchions of the Common Tower System. The tests were conducted using the University’s column testing machine in the Heavy Structures Laboratory.

Technical Guidance

We provide technical guidance for construction project teams when deciding how to identify the most efficient and effective means of vertical access distribution for a project site.

Tender Designs

We provide information and pricing to the client in order for them to fully understand the access scheme recommendations. This includes layout drawings through to 3D views of the Common Tower & hoists and their interaction with the building under construction.

Detailed Designs

Once we have been engaged by the client and a Common Tower & hoist scheme has been accepted by the project team, we complete the detailed design and provide the necessary engineering documentation. A full set of drawings are completed for the project and the installation teams.

Engineering & Component Testing

Engineering & Component Testing Projects